Product Description

The load cell 1010/1015* is one of the original milestones of weighing technology being the first mass produced platform load cell. It is estimated that there are more than 10-million units in operation in both industrial scales as well as in filling, dosing and packaging machines.

It has a very unusual design (triple beam) which gives it a high natural frequency and hence a fast response in dynamic applications. The 1010/1015* has an integrated overload screw, which reliably protects the load cell against damage if excessive load is applied.

The Model 1010/1015* is manufactured using an optimised complex machining process. This ensures that there will be no measurement error when the load is placed off centre, eg in a corner of a platform.

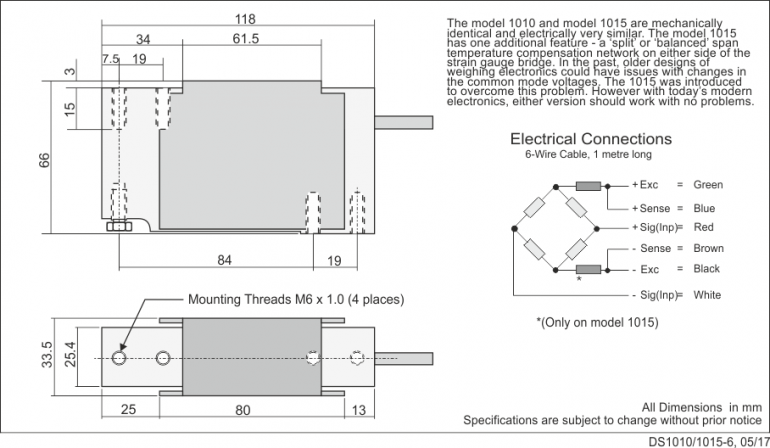

A platform scale can easily be constructed using this load cell. You simply have to mount the load cell between two steel or aluminum plates up to 350 mm square, securing the bottom plate to the threaded holes in the underside of the load cell (cable entry end) and the top plate to the threaded holes on the upper face (opposite cable entry end). The load cell then has to connected to a suitable display or readout.

The 1010/1015* load cell is fitted with a 6 core shielded cable as standard. Special cables and lengths are available on request.

For additional sealing, the model 1010/1015* can be provided with optional Sylgard protection